- 2023-06-12

- 594

- 5 Comments

What are the parts of plastic mold

What are the parts of plastic mold

1. Sprue (gate sleeve) :

Directly in contact with the nozzle of the beer machine, the beer machine must pass through the nozzle before entering the mold core;

2, positioning ring (ring) :

It is used for easy alignment when the mold is on the beer machine (mold frame);

3. Panel:

Support the whole mold together with the base plate;

4, thimble protection switch:

When the thimble board is not returned to the position, the switch is not connected, at this time the line is disconnected, the front and back mold can not close the mold, so as to ensure that the front mold will not hit the thimble because the thimble is not returned to the position, so as to avoid mold damage;

5. Top rod hole:

After the forming is completed, the top rod pushes the thimble plate, and the thimble plate pushes forward to push the product out;

6, water rod:

Used to open the nozzle plate when opening the mold, so that the nozzle is easy to take out;

7. Guide post:

It plays a guiding role in the front and back mold closing (a total of 4);

The "guide column" in the mold is also called "guide column", and the role is to guide.

The function of the guide device of the die is to guide the upper die and the lower die to the correct position. The most common guide device is the guide post guide sleeve.

8. Water transport interface:

When the mold temperature continues to rise during production, the water can make the mold produce at a constant temperature, thus ensuring the stability of the product;

9. Inclined guide post:

When opening the mold, if the spring of the row position does not work, the inclined guide will drive the row position back out (the inclined guide is fixed on the front mold), also called the beveled edge or bent pin: used as a moving slider to do repeated movement;

10, shovel machine:

When the mold is closed, the line position is pushed forward by the inclined plane, and the shovel is fixed on the front mold (the matching surface of the shovel and the line position is the inclined plane);

11. Line bits:

Mounted on the back mold;

12. Row position gasket:

Used to increase the wear resistance of rows; (The product has a buckle, so it needs to be done)

13, back stitch:

It can guide the ejection and retreat of the thimble, and ensure that the thimble board can be withdrawn in place after the front and back molds are closed, because the return pins and the front molds are in contact with the mold embryo (a total of 4 pieces); (The product relies on the ejection of the thimble, inclined top, and cylinder ejection)

14. Cylinder needle:

Fixed on the bottom plate, when the thimble plate is pushed out, the cylinder needle remains motionless; Lock a headless screw at the head of the cylinder needle cup. The diameter of the headless screw depends on the size of the mold, such as a small mold, that is, a distance of 5MM, and a large mold that is 10MM.

15. Cylinder:

When there is a circular bone position on the product, and the depth of the bone position is relatively high, and the mold is easy to stick when the mold is produced, it is necessary to consider making a cylinder; The cylinder has an ejection effect, and the cylinder is fixed on the thimble plate.

16. Inclined top:

When exiting the mold, the inclined top goes up the top along the inclined direction (Angle 90°). After the inclined top exits the mold, the distance between the inclined top and the product buckle should be there

Above 0.5MM, to ensure that the product will not buckle to the inclined top;

17. Cylinder (pipe jacking) :

Ejecting the product from the mold core, the role is the same as that of the thimble, but it is generally used for stripping the cylinder with a fine hole in the center of the product;

18, cylinder needle:

It is used for the molding of the column position hole of the product, and is used with the cylinder, and is not used for demoulding;

19, support column (support head) :

Support B plate, due to pressure deformation during injection; Lock screws from the bottom of the panel to the bottom of board B;

20, garbage nail:

Supporting the thimble board, due to its small area, can prevent garbage accumulation on the top, so that the thimble board uneven or deformed; Draw from the bottom of the thimble board;

21, water transport hole:

For the effective cooling of the mold, so that the mold temperature is kept within a certain range;

22, throat:

Installed on the mold water transport hole, used to connect the cooling water throat of the beer machine, generally made of copper;

23, pulling rod:

A. Splitter pull rod: Because the plastic stored in the splitter is not easy to fall off, it is easy to fall off the cold material when opening the mold;

B, gate pulling rod: in the opening of the mold from the gate sleeve to pull out the main channel condensate to facilitate separation from the injection molding machine nozzle, generally at the end of the cold hole, pulling rod diameter is equal to the diameter of the inner diameter of the big end of the gate in order to trench the cold material;

24, slider:

It is an important part to complete the side core-pulling. It is used with the guide chute and driven by the inclined guide column for side core-pulling.

25. Row position (slider slot) :

It is a sliding transverse die, generally used when the side of the product has a concave and convex shape, the moment line (T-slot) and dovetail type, so that the slider drives the forming core smoothly and accurately, and the width tolerance can be relaxed;

26, spring:

Play a reset role;

27, small pull rod:

It has the same function as the tie rod, plays the limiting role, and is the main accessory in the double parting surface mold (fine water mouth);

28, limit nail (stop block) :

Play a limiting role, the mold is often used in the roof limit (on the back of the B plate or the front of the roof);

Limit pin: limit the ejection stroke of the thimble plate;

29, exhaust tank:

It is used to discharge the air in the mold itself and the gas generated by the heating of the plastic. Commonly processed in parting die, surface and hot runner plate. There is also a guide column vent slot, which is generally processed in the upper splint and the square iron next to the guide sleeve;

30, positioning steel ball:

It is mainly for the slider (row seat) to stop;

31, hanging ring:

Also called circocephalus; For hanging die;

32. Zhongtoshi:

Installed on the top nail group plate, used to guide the ejecting system;

33, resin opener (nylon rubber plug) :

It is mainly used to increase the opening resistance between fixed and moving molds to ensure that the runner plate and the panel and the fixed template are opened before the fixed template and the moving template;

Design considerations:

(1) The nylon plug with resin opening and blocking should be embedded in the moving template 3 MM;

(2) The opening of the template should be rounded R, and polished to prevent scratching the nylon plug, such as bevel chamfer, it is easy to grind the surface of the nylon plug, reduce the service life of the nylon plug;

(3) Exhaust device should be added to the bottom of the template hole;

(4) The holes in the fixed template matched with the nylon plug should be polished;

(5) Do not refuel on the nylon plug, because refueling will reduce its friction;

(6) The product itself has been trimmed by a precision automatic car, and the roundness can reach within 0.01MM, so the contact area of the nylon plug is improved;

⑺ do not need to lock the screw too tightly when using;

(8) Determination of the number of nylon plugs: 12 * 4 diameter with mold mass below 100 kg; 500 kg below the diameter of 16 * 4; Less than 1000 kg with a diameter of 20 * 4, if more than 1000 kg is increased to more than 6;

34, heat insulation board:

Because the mold temperature is higher than the injection molding machine, the main function of the heat insulation board is to prevent heat dissipation;

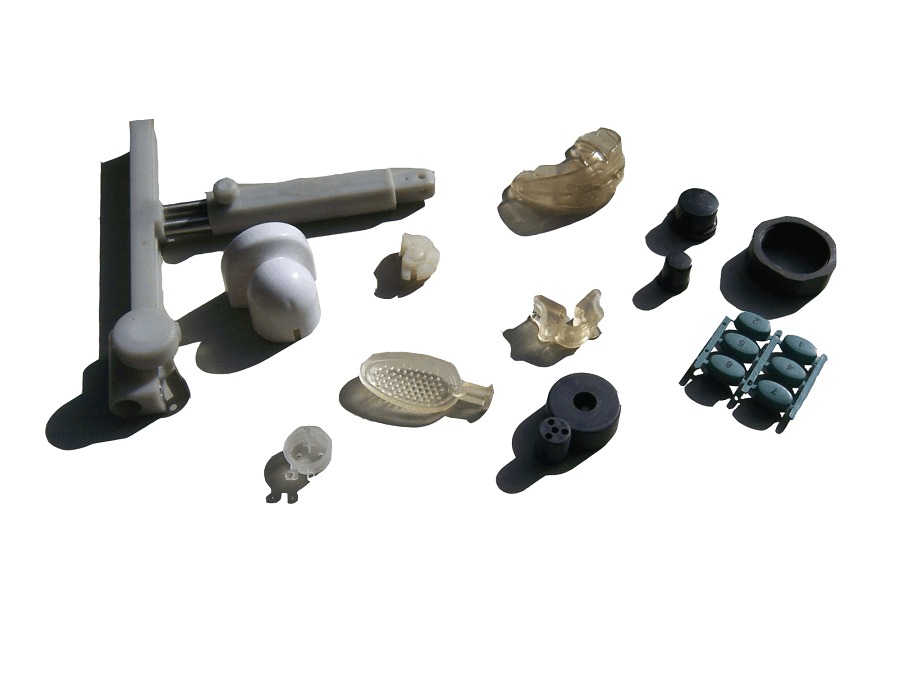

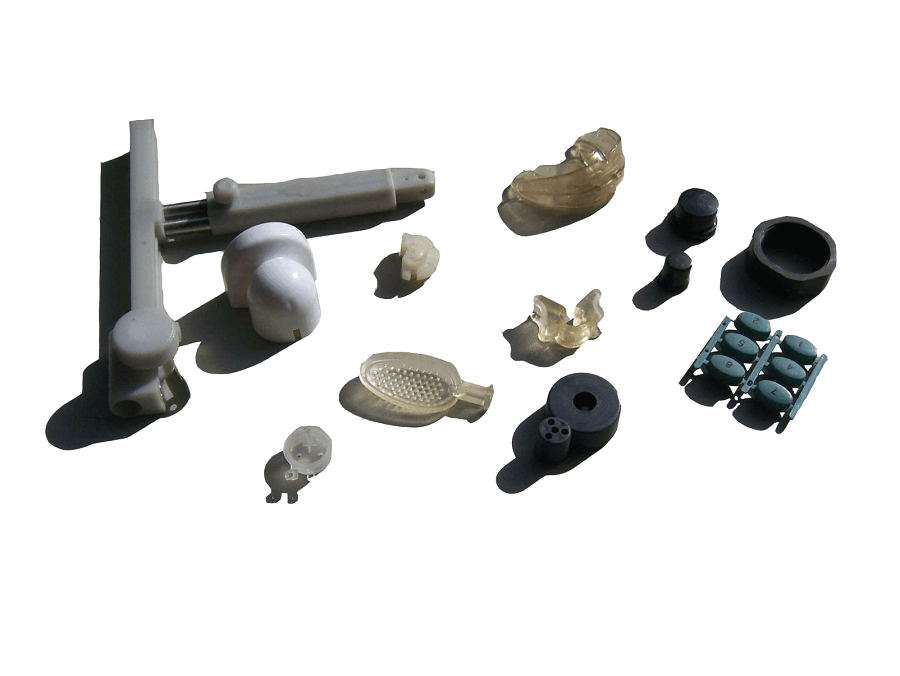

35, insert: save material, save mold and save labor;

A, in general, the bone position is higher than 8 MM to consider making inserts to facilitate the saving of mold and exhaust;

B, the insert should have a distance of 0.05 ~ 0.1MM from the edge to prevent excessive saving of materials;

C, for the convenience of mold saving and making inserts;

D, the product has a stop to make large inserts, inserts do not insert through; (0 ~ 1 degree bevel)

E, cylindrical, round holes should be considered to make inserts to facilitate processing, inserts and circular inserts, if the top glue is uneven or asymmetrical shape, to do positioning anti-rotation;

36, screw rod:

Fixing the opening stroke of the upper fixing plate and stripper plate;

37, drawing water plate:

Fixed drawing needle;

38, front and rear die inserts:

Fixed runner plate and front and rear die;

39, drawing needle:

Pull the water nozzle;

40, after the mold needle insert set:

Mainly used for product cup molding;

41. Thimble:

Ejecting the material belt to separate the material belt from the mold; It is a part of the ejection site;

42, external pull rod:

Used to open the line cavity and limit the opening distance of the line cavity;

43, flat thimble (flat pin) :

Mainly used for the ejection of the bar part of plastic products, as well as the long glue position, the round thimble can not be placed down are selected flat thimble; It is the place where the gum site is relatively deep;

44, Copper:

Where it can not be machined, it is machined with copper metric shape;

The purpose of manufacturing copper male is to prepare for the glue site (such as bone) that can not be processed, make it into the shape of the glue site, and then the electric spark will be processed out of the glue current that can not be processed, and the reverse buckle needs to be manufactured by the inclined guide pillar;

45. Occipital position:

Forming the local shape of the product;

46, Tiger mouth:

Positioning the front and rear mold;

47, insert needle:

Is a part of the formation of local colloidal sites;

48, with support needle:

For ejecting products from holes less than 2 MM;

49, shovel:

It is installed on the opposite side of the slider and behind the inclined guide post. Generally, the Angle of the lock module should be greater than the Angle of the inclined guide post 3 to 5°, and the lock module is on the fixed mold when the slider is in the moving mold. When the mold is closed, the lock module is behind the slider to resist the slide block, to prevent the slide block from backward displacement due to the pressure of injection molding, and then affect the size of the injection part. The lock module plays the role of locking the mold slider. When the opening die is separated from the setting die, the lock module is also separated from the slider. At this time, the slider will be taken backward by the inclined guide column or hydraulic core-pulling mechanism to complete the core-pulling process.

50, lock module:

It is not allowed to open the dynamic fixed die during the process of lifting, loading and unloading and transportation of the die to protect the role of the die. Be sure to open it during injection molding. Generally, a small mold is installed, and a large mold is installed with 2 or more.

51, pry die Angle:

Pry open the corners of each plate of the mold;

Related Posts

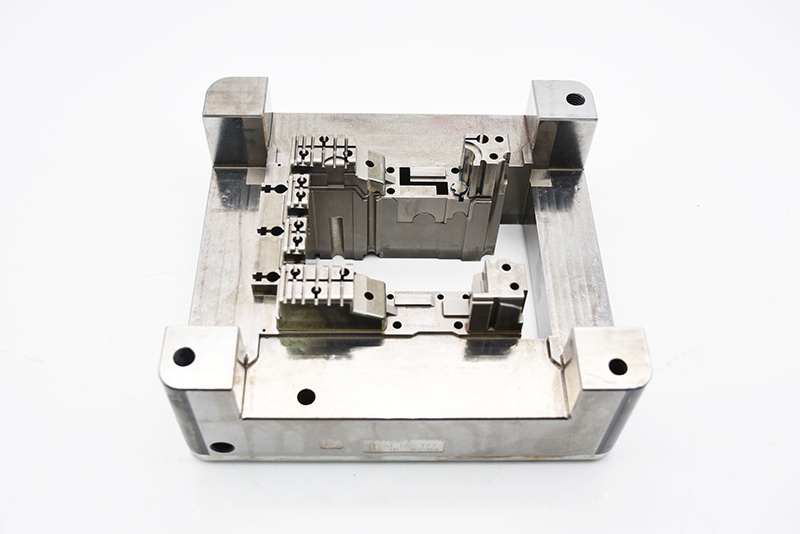

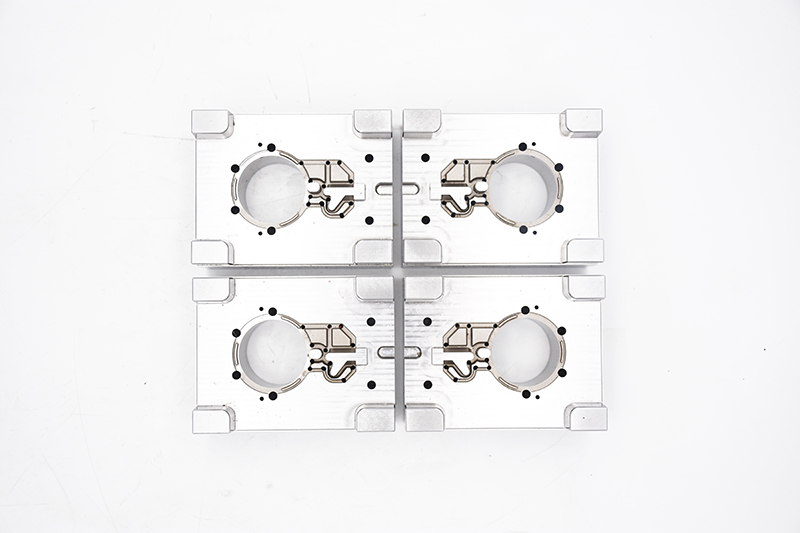

- Precision Irrigation mold cavity and spare parts

- zefu-mold

- 708