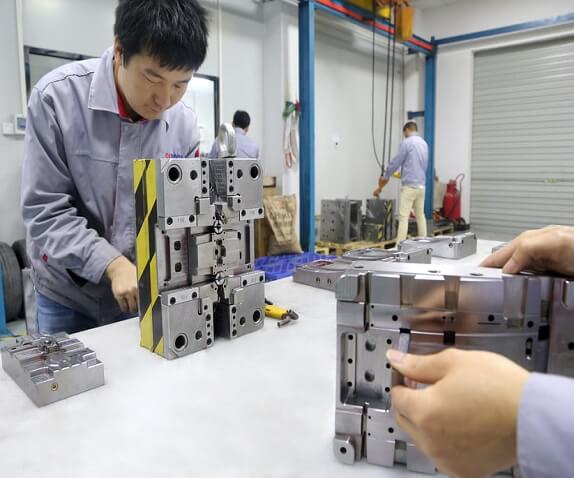

Mold making

Customized precision mold cavity and mold making

One-stop solution

Precision molds

+

+

We Manufacture Molds

For a Variety of Industries

Material application

Machinery Production

Get a solution for all your Industries needs.

Zefu Mold Provides

Mold For Your Business

Our engineering team with years of experience in mold manufacturing,

can quickly and effectively solve the problems on the mold. At the same time,

we also have sufficient advanced manufacturing equipment and precision

measuring equipment to ensure perfect quality and satisfied delivery.

Effective engineering communication

Advanced equipment

Constantly reinventing manufacturing tech

Guarantee the quality and delivery

You can simply understand some common questions and replies about our mold manufacturing...

-

Will you provide the drawing?Yes, we will provide the drawing of 3D container makeup mold for your approval. We have a professional drawing engineer to the mold drawing design, modification, parameters and so on audit.

-

What services can we provide?

1. Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDUs;

2. Accepted Payment Currency:USD,EUR;

3. Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

4. Language Spoken:English,Chinese,Spanish,French,Russian

-

How can we guarantee quality?

1. Always a pre-production sample before mass production;

2. Always final Inspection before shipment; -

What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24 hours;

2. Well trained and experienced staffs to answer all your enquirie in fluent English.;

3. Offering the support to solve the problem in the application or selling period.;

4. Competitive prices based on same quality.;

5. Guarantee samples quality same as mass production quality. -

How long is the lead-time for mold?

It all depends on the products' size and complexity. Normally, the lead time is 15-25 days.